Tape ODM Solutions

From concept design and material selection to finished product packaging—allowing you to bring high-quality tape products to market under your own brand without investing in R&D or production infrastructure.

Home » 3M Die Cuttable Tape Solutions » Tape ODM

What Is Tape ODM?

Tape ODM (Original Design Manufacturer) refers to a company that not only manufactures adhesive tape products, but also takes responsibility for the design, development, and functional customization based on the client’s application requirements. Unlike OEM, where the client provides the specifications, an ODM creates original tape solutions from concept to finished product, often under the client’s brand. What we offer as a tape ODM partner:

Product R&D and Design

Design tape products with reasonable structure and excellent performance according to the needs of the target market, including functional characteristics such as viscosity, fire resistance, high temperature resistance, thermal conductivity, insulation, etc.

Material Selection and Verification

Recommend and test the most suitable adhesive materials for your application scenarios to ensure stable, safe and compliant product performance.

Mold and Process Development

Customize die-cutting molds and production process flows to achieve precision die-cutting, lamination, composite and other processing methods.

Brand Customized Packaging

Paper tubes, cartons, independent packaging, blister packaging, and outer boxes are designed for customers

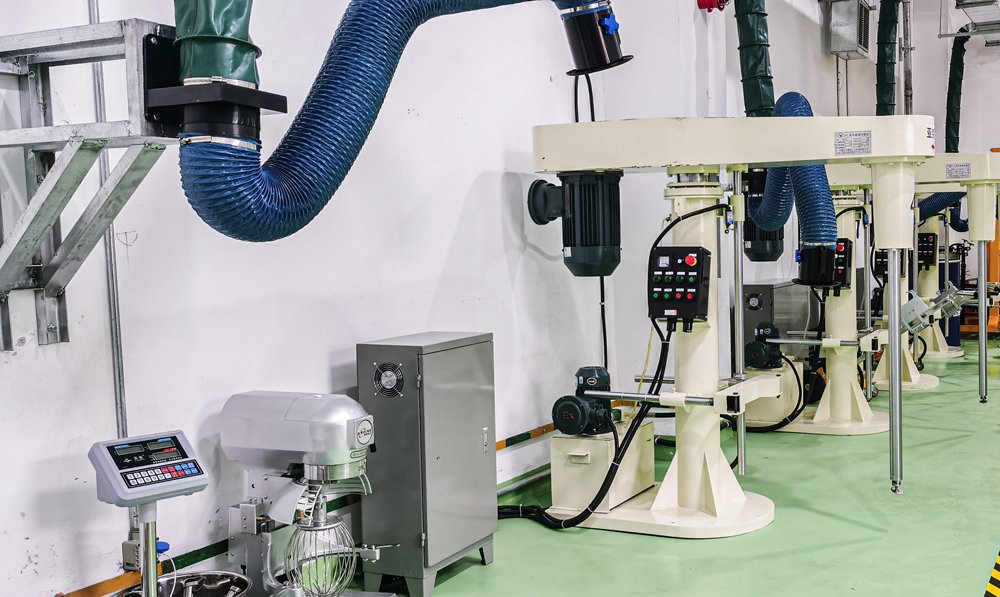

Mass Production and Quality Control

With 6 large factories, 200+ advanced equipment, and supporting clean workshops, we can meet the mass production and quality traceability needs of products of different levels.

Global Logistics and After-sales Support

Provide global distribution solutions and after-sales technical support to help you efficiently expand overseas markets.

Our Advantages

We provide customers with one-stop solutions from product design, material development to batch manufacturing and brand packaging, helping you easily own your own brand of tape products.

Adhesive Formulation

Customized adhesives are developed to meet performance and bonding needs.

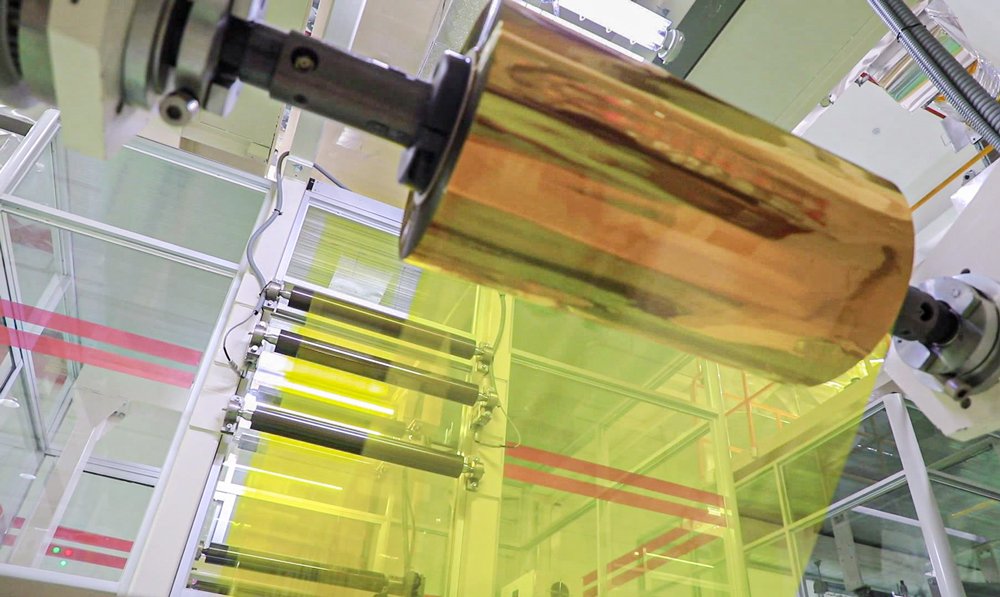

Base Film Preparation

PET, foam, tissue, or other backing materials are selected and pre-treated.

Coating Process

Adhesive is evenly coated onto the base film using precision coating equipment.

Rewinding

Coated jumbo rolls are rewound to ensure uniform tension and consistency.

Slitting / Recutting

Rolls are slit into custom widths and lengths based on application needs.

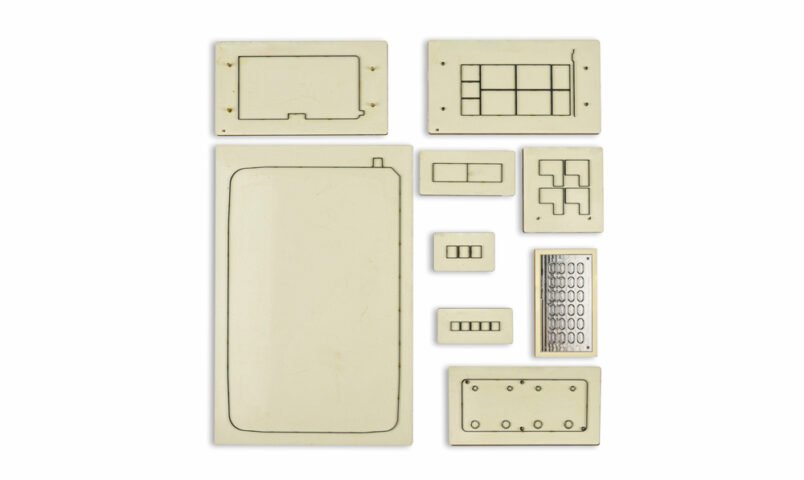

Die-Cutting

Tapes are converted into precision shapes or parts according to customer specs.

Quality Inspection

Each batch undergoes testing for adhesion strength, thickness, and appearance.

Packaging

Tapes are professionally packaged for safety, traceability, and delivery.

28 Years

A partner you can count on. Quality you can trust.

ODM Process

Our ODM process is designed to help you quickly launch high-quality tape products under your own brand—without the burden of in-house R&D or manufacturing.

1. Requirement Analysis

We begin by understanding your application, performance goals, market needs, and branding expectations.

3. Sample Prototyping

We produce samples for functional testing, validation, and refinement—ensuring the product meets your requirements.

5. Private Label Packaging

We help design and produce branded labels, packaging, and documentation tailored to your identity.

7. Logistics & Global Delivery

Finished products are packed, shipped, and delivered worldwide—with full compliance and export documentation.

2. Material & Structural Design

Based on your needs, our engineers select or develop suitable adhesives, backings, liners, and constructions.

4. Tooling & Process Setup

Custom die-cutting tools and production lines are prepared for efficient, consistent mass production.

6. Mass Production & Quality Control

With 6 factories and over 200 machines, we ensure large-scale production with strict QC at every stage.

Frequently Asked Questions

Whether you’re new to OEM partnerships or seeking technical clarity, this section will help guide your decision-making process.

OEM means you provide the product design and specifications; we manufacture it. ODM means Yousan provides product design, materials, and structure—you just add your brand.

Yes. While ODM is based on our existing designs, we offer semi-custom options, including dimensions, adhesive strength, backing materials, and more.

For existing ODM products with minor adjustments, lead time is usually 2–4 weeks. For fully customized designs, development may take 4–8 weeks including testing and approvals.

Let’s Connect with Yousan

Contact our team for one-on-one technical support and tailored adhesive tape solutions.