Precision Die-Cutting Solutions

With over 28 years of experience, expert team members, and state-of-the-art equipment, we can handle all of your die-cutting needs

Home » 3M Die Cuttable Tape Solutions » Precision Die-Cutting

Precision Die-Cutting

Yousan is a world-class flexible materials converter with over 28 years of diverse industry and performance materials experience. Our expert team has processed hundreds of different materials

High Accuracy & Consistency

Enables repeatable, micron-level cutting tolerances for complex shapes—essential for electronics, automotive, and medical applications.

Improved Efficiency

Die-cut parts arrive ready-to-use—reducing manual trimming, assembly time, and process steps.

Custom Shapes & Functional Layers

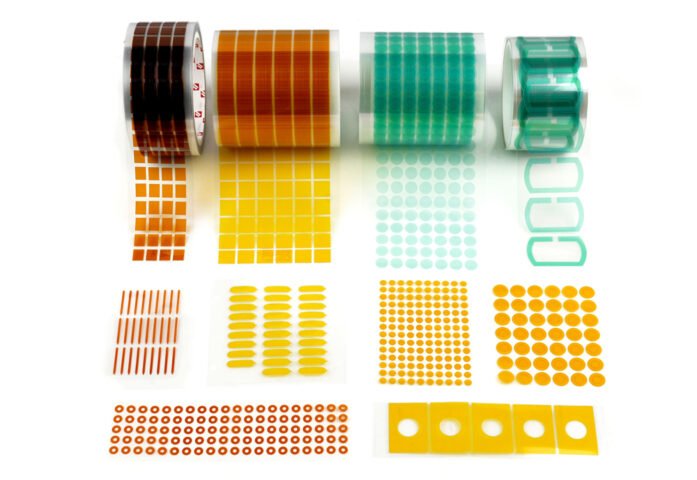

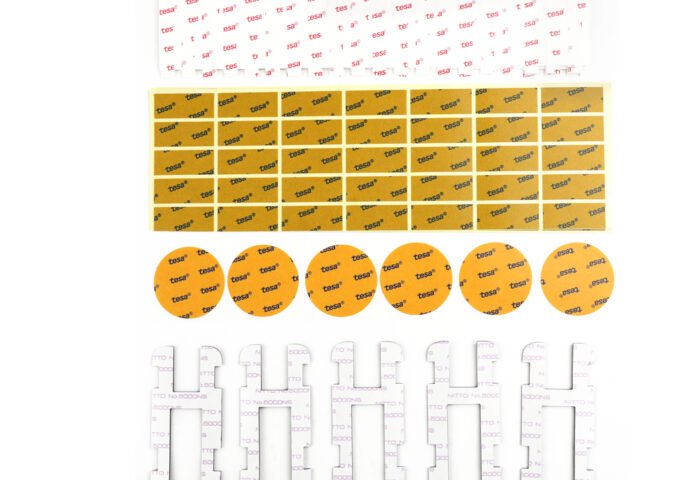

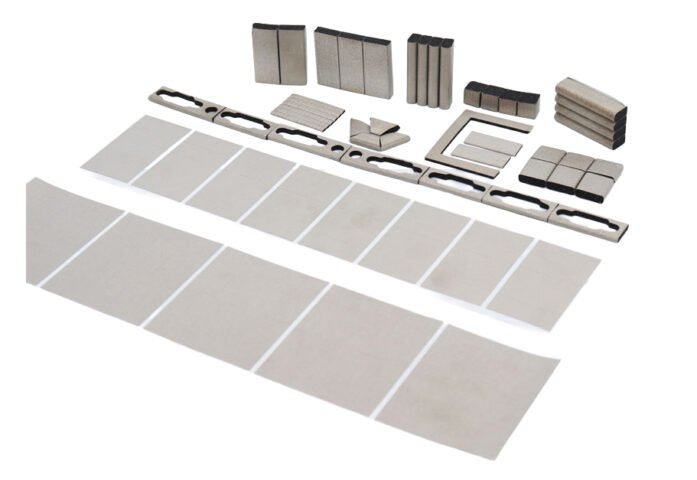

Supports complex multi-layer constructions with adhesive, foam, PET, release liners, and more.

Clean Edges & Debris-Free Processing

Ideal for cleanroom and dust-sensitive applications thanks to laser/rotary die-cutting options.

Material Waste Reduction

Optimized material usage through CAD design and tight-nest layouts during production.

Ready for Automation

Die-cut formats can be roll-fed or sheeted for integration into automated assembly lines.

What Is Precision Die-Cutting?

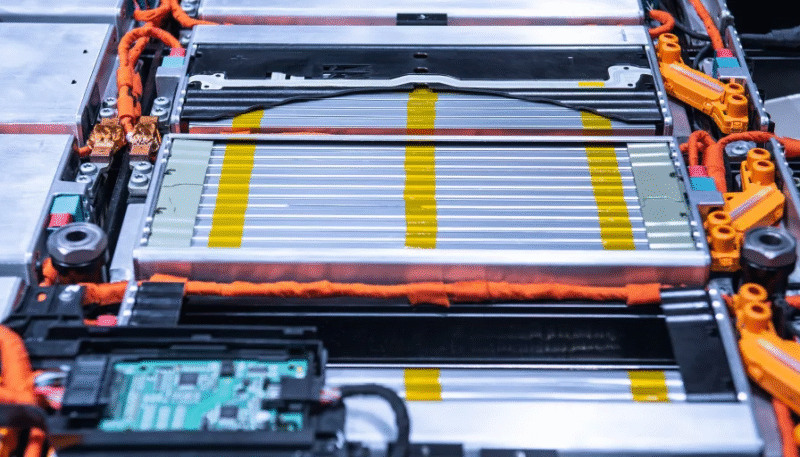

Precision tape die cutting is a process of cutting and processing tape materials using die cutting technology. Die cutting is the process of accurately cutting tape materials into the required shape and size by using a mold of a specific shape and a pressure device. This process is usually applied to tape products that require high precision and complex shapes, such as protective films for electronic devices, sealing tapes for automotive parts, adhesive materials for medical devices, etc.

Why Precision Die Cutting Matters

Precision die cutting plays a critical role in the manufacturing of components where accuracy, consistency, and material integrity are non-negotiable.

Whether it's in medical devices, consumer electronics, automotive systems, or energy storage, even the smallest deviation can lead to product failure or performance degradation. By leveraging advanced cutting technologies and tight-tolerance processes, precision die cutting ensures:

1. Accurate dimensions and clean edges — vital for sealing, insulation, or optical clarity.

2. Material protection — preserving the functional layers of sensitive tapes, films, and foams.

3. High repeatability — essential for mass production and multi-cavity component fabrication.

4. Reduced waste and better yield, improving cost-efficiency and sustainability.

5. Seamless integration with automated assembly lines.

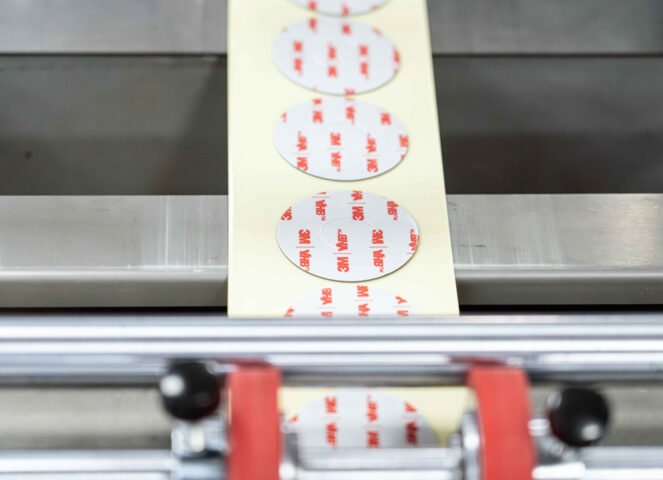

Production Process Show

Discover how high-performance tapes are made—from coating and curing to slitting and inspection. Precision at every step ensures reliable quality and performance.

Industries & Applications

Yousan tape products and die-cutting solutions are widely used in multiple high-standard industries, meeting the multi-functional needs of bonding, fixing, sealing, insulation, buffering, thermal conductivity, etc. in different fields.

Frequently Asked Questions

By leveraging our unique manufacturing processes, including precision die-cutting, we can create customized, innovative solutions designed to help our customers overcome a variety of product performance and process efficiency challenges.

Lead times vary by complexity and tooling requirements. For standard tapes and simple shapes, prototypes can typically be produced within 3–7 working days.

Most industrial tapes can be die-cut, including:

Double-sided tapes

Thermal interface tapes

Conductive/EMI shielding tapes

Foam tapes

PET/PI tapes

High-temperature and specialty adhesive tapes

Common methods include:

Rotary die-cutting – Fast, suitable for roll-to-roll production

Flatbed die-cutting – High force, suitable for thicker materials

Laser cutting – Burr-free, precise, for intricate or small features

Tolerances can be as tight as ±0.05mm depending on the material, shape complexity, and tooling.

Let’s Connect with Yousan

Contact our team for one-on-one technical support and tailored adhesive tape solutions.