Die-cutting Solutions

Providing a variety of high-performance bonding solutions for the industrial die-cutting field.

Home » 3M Die Cuttable Tape Solutions

Industrial Die-cutting Tape Solutions

28 more years of innovation with Yousan industrial adhesive tapes. From custom die-cut parts and rapid prototyping services to supply chain management solutions, Yousan offers a full range of innovative die-cutting and converting capabilities — including precision converting of foam tape, kapton tape, double-sided tape, and thermal pad materials for electronic, automotive, and industrial applications.

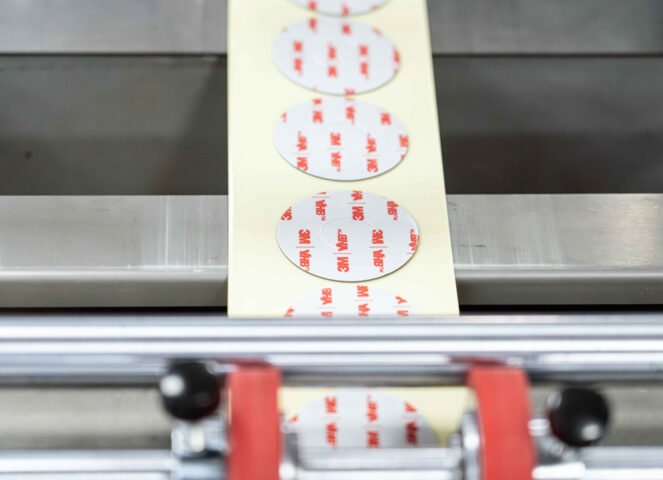

Pre-Cut Foam Tape

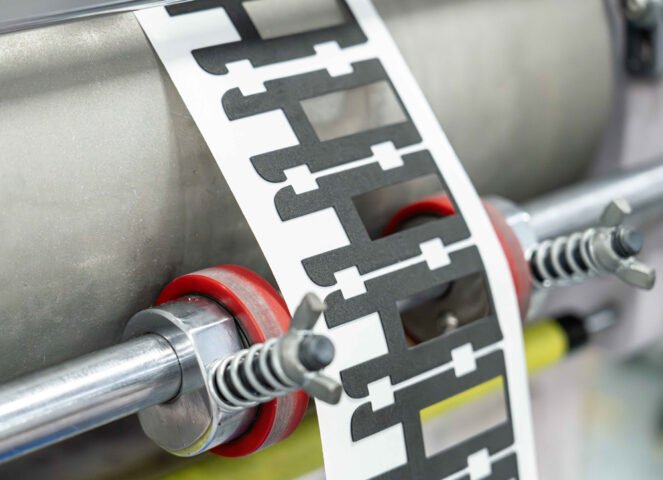

Whether your die-cut parts require a straightforward steel rule manual die, a multi-step servo-controlled matched progressive rotary system with integrated island placement, or anything in between, Yousan has the solution. With over 28 years of experience, expert team members, and state-of-the-art equipment, we can handle all of your die-cutting needs — including precision converting and custom fabrication of 3M die cuttable tape for electronics, automotive, and industrial applications.

Our clean rooms have been carefully designed to meet the strict standards and quality requirements of the highly specialized industries that require that their parts be made in a low air particulate, temperature- and humidity-controlled, and sanitary environment. An ic lass 1000 clean room dust typically benefits industries like medical, electronics, pharmaceutical, health & beauty, and low altitude economy.

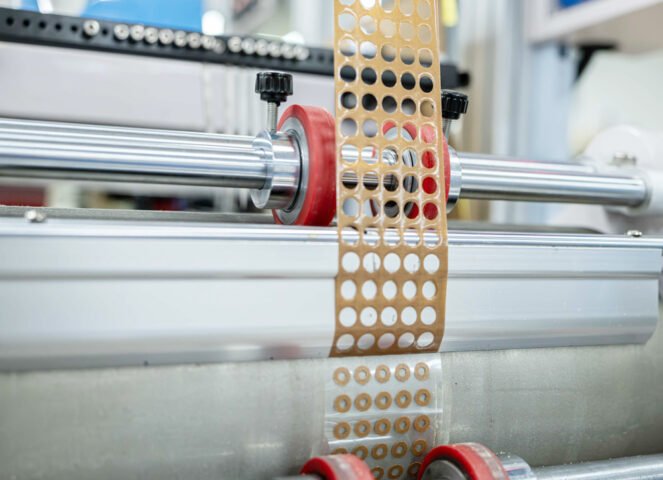

Custom Die Cut Tape

Pre Cut Tape

High-precision die-cutting services for composite materials are available, utilizing advanced equipment and in-depth materials expertise. These services support complex multi-layer laminates, technical films, foams, and adhesive tapes—precisely cut to meet exact specifications for applications such as sealing, insulation, cushioning, and EMI shielding.

As a trusted adhesive tape OEM manufacturer, Yousan offers comprehensive services from tape formulation to branding. Whether you need customized dimensions, die-cut parts, or private label packaging, we deliver precision, performance, and flexibility to support your brand and market growth.

Tape Converting Services

3M Die Cuttable Tape

End-to-end ODM (Original Design Manufacturing) services are available for adhesive tapes — covering everything from material engineering and functional design to prototyping and mass production. These services help develop customized tape solutions aligned with specific product and market requirements, making them ideal for brands seeking technical innovation without investing in in-house R&D.

Let’s Connect with Yousan

Contact our team for one-on-one technical support and tailored adhesive tape solutions.