Technical data

| Product Code |

Color | Total Thickness [um] | Backing [mm] | Adhesive | Initial Tack [mm] |

180° Peel Strength [N/inch] |

Retentivity [hour] |

Long-Term Temperature Resistance [℃] | Short-Term Temperature Resistance [℃] |

| P3205AB | Transparent/Black | 50 | 0.012 | Acrylic+ silicone |

≤100 | A≥8 B≥7 |

≥24 | 80 | 120 |

| P3208AB | Transparent/Black | 80 | 0.025 | Acrylic+ silicone |

≤100 | A≥10 B≥8 |

≥24 | 80 | 120 |

| P3210AB | Transparent | 100 | 0.025 | Acrylic+ silicone |

≤100 | A≥16 B≥12 |

≥24 | 80 | 120 |

| P3213AB | Transparent | 125 | 0.025 | Acrylic+ silicone |

≤100 | A≥14 B≥12 |

≥24 | 80 | 120 |

| P3214AB | Transparent | 140 | 0.025 | Acrylic+ silicone |

≤100 | A≥18 B≥14 |

76854 | 80 | 120 |

Legal Disclaimer

The values given are typical values, and do not constitute a specification. We recommend testing the suitability of the self-adhesive tape for the designated application or use. Please contact us or e-mail info@ysdiecut.com to determine product availability.

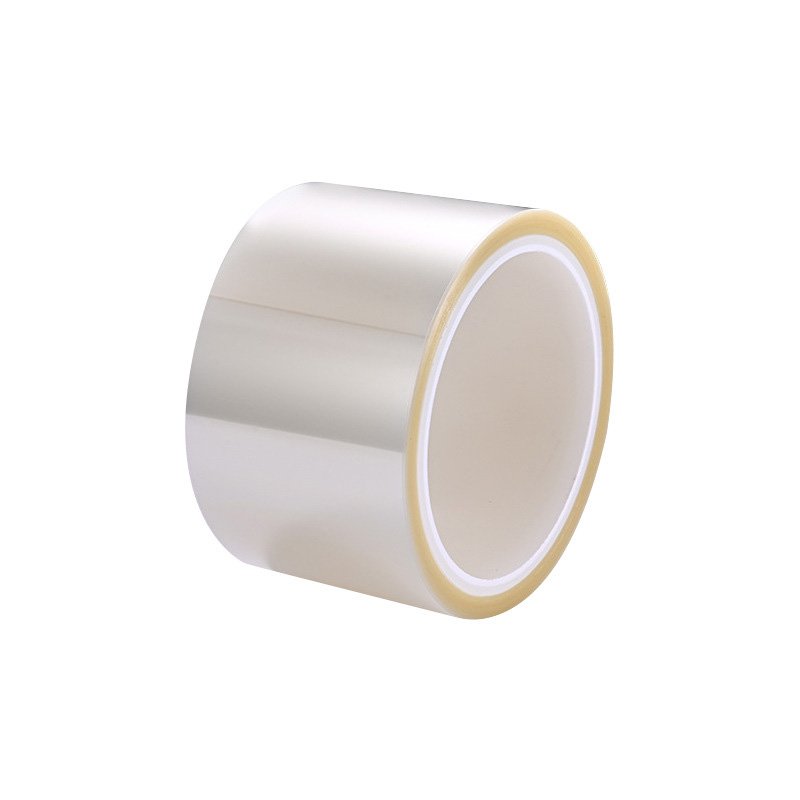

Silicone/Acrylic PET Double-Sided Tape Manufacturer

Yousan New Materials

Storage

It is recommended to store in a clean and dry place, away from direct sunlight to prevent damage to the packaging, and to avoid storing with volatile solvents. Store at 25±5°C and humidity at 50±5%.