Flexible Materials Converting Solutions

Tailored converting services for flexible materials—designed for performance, precision, and production efficiency.

Flexible Materials Converting

Provides advanced converting services for a wide variety of flexible materials—including adhesive tapes, protective films, foam, fabric, and technical laminates. Our precision die-cutting, laminating, and slitting processes enable efficient production of custom parts for electronics, automotive, medical, and industrial applications.

High-precision die-cutting

Advanced die-cutting equipment supports ±0.1mm or even higher precision, ensuring part consistency and fitting performance, meeting high standards such as electronics and medical.

Strong material compatibility

Can handle a variety of flexible materials, including tapes, foam, PET/PI films, conductive/thermal conductive materials, non-woven fabrics, shielding materials, etc., suitable for different application scenarios.

Multi-layer structure processing capabilities

Supports one-stop processing such as multi-layer composite, automatic lamination, back glue, and waste discharge, simplifying the customer assembly process and improving overall efficiency.

Clean environment guarantee

With Class 100~Class 1000 clean room die-cutting capabilities, it is suitable for industries with extremely high cleanliness requirements, such as medical, display modules, semiconductors, etc.

Fast proofing and flexible production

Quickly respond to customer customization needs, support from small batch proofing to large batch mass production, full process traceability management, and guaranteed delivery.

Applied in multiple industries

Widely serving high-end manufacturing fields such as consumer electronics, automobiles, new energy, medical equipment, optoelectronic displays, aerospace, etc.

What Is Flexible Materials Converting

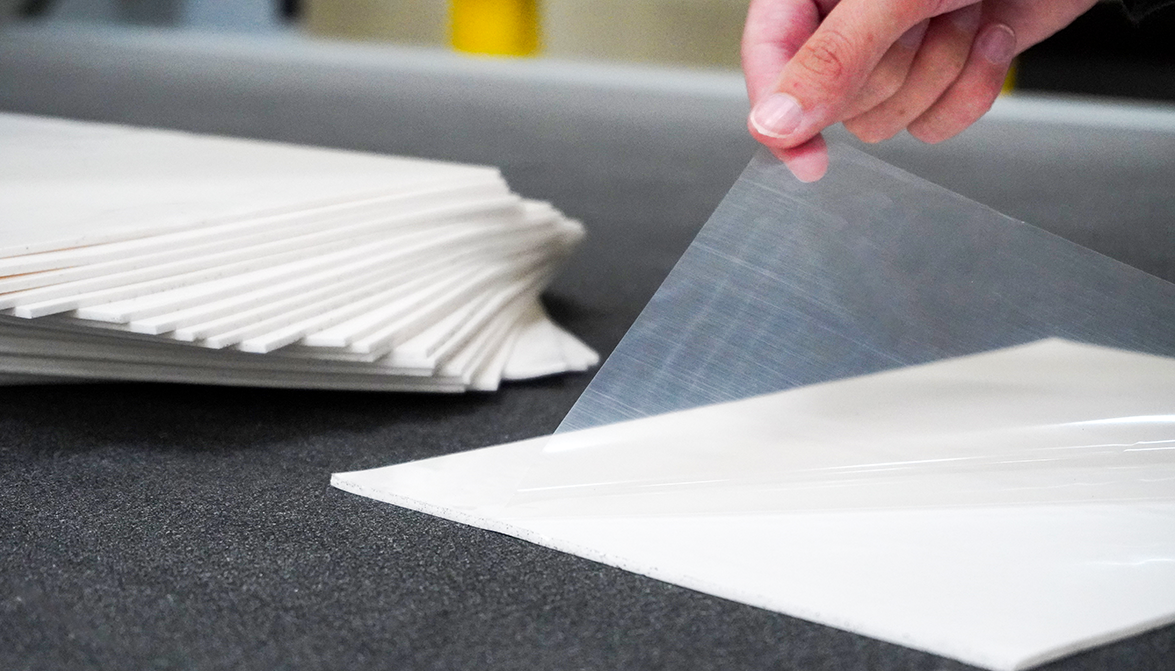

Flexible materials converting refers to the process of transforming soft, roll-based materials—such as adhesive tapes, films, foams, fabrics, and laminates—into precisely shaped and application-ready components. This process includes various specialized techniques such as: Die-cutting (flatbed, rotary, laser), Laminating, Slitting and rewinding, Multi-layer assembly, Kiss-cutting and liner removal.

Flexible Materials Converting Benefits

• High Precision

• Versatile Material Compatibility

• Customization & Multi-Layer Integration

• Cleanroom Capability

• Prototyping to Mass Production

• Efficiency & Cost Control

Flexible materials converting bridges the gap between raw materials and ready-to-assemble components—accelerating innovation and manufacturing efficiency.

Industries & Applications

Flexible materials converting is widely used in industries such as electronics, automotive, medical, aerospace, and new energy, where precision, cleanliness, and material integrity are essential.

Frequently Asked Questions

Find quick answers to common questions about our adhesive tapes, die-cutting services, and customized solutions. We’ve compiled the most frequently asked inquiries from our clients to help you get the information you need—fast and efficiently.

We work with a wide range of materials including double-sided tapes, conductive films, optical films, thermal interface materials, foam, PET/PI, and more. Custom material sourcing is also available.

Industries such as electronics, automotive, medical devices, consumer products, new energy, aerospace, and display technologies all benefit from precise, application-ready components.

MOQ varies depending on the complexity, material type, and order size. We offer flexible volumes—from prototyping to full production runs.

Yes, we operate ISO-certified cleanrooms (Class 100 to Class 1000) to meet the strict cleanliness standards required by medical, optical, and semiconductor industries.

Simply contact our team with your drawings, specifications, or material requirements. We’ll evaluate the design, recommend materials if needed, and provide a quote and prototype timeline.

Yes. Our application engineers can recommend suitable materials based on your product’s functional needs—such as adhesion, insulation, thermal management, EMI shielding, or optical clarity.

We accept most common CAD formats, including DXF, DWG, AI, and PDF. If needed, we can also assist with file conversion or drawing adjustments.

Get in Touch with YouSan

Contact our team for one-on-one technical support and tailored solutions.