Tape Applications in Heat Shielding

Precision die-cut tape solutions are engineered to manage heat, protect components, and optimize performance in demanding environments across industries such as automotive, electronics, and aerospace.

Home » Applications » Heat Shielding

Thermally Conductive Materials Help Improve Heat Dissipation Efficiency and Extend Equipment Lifespan.

Heat shield tapes effectively control or redirect heat to protect sensitive components. With advanced adhesives and precision die-cutting, they improve thermal management, enhance reliability, and extend product life in automotive, electronics, and aerospace applications. Typical applications include:

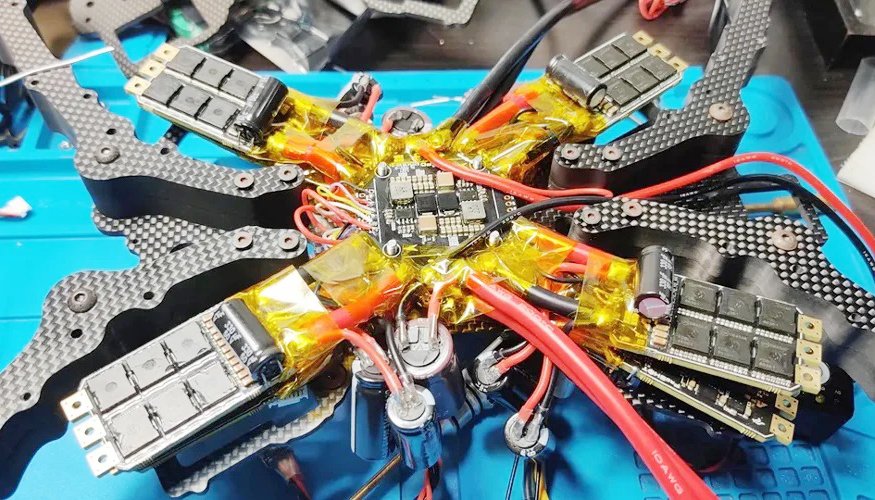

Battery Thermal Management

In lithium battery modules, thermal insulation layers, fireproof layers, and thermal insulation gaskets are commonly used to enhance safety and thermal control. These components often utilize flame-retardant die-cut tapes, as well as aluminum foil or copper foil combined with foam composite tapes.

Automotive Heat Shielding

Components such as engine compartments and electronic control modules utilize heat insulation reflective layers near heat sources. Common materials include high-temperature foil, glass fiber cloth tape, and ceramic fiber die-cut gaskets.

Electronics Heat Insulation

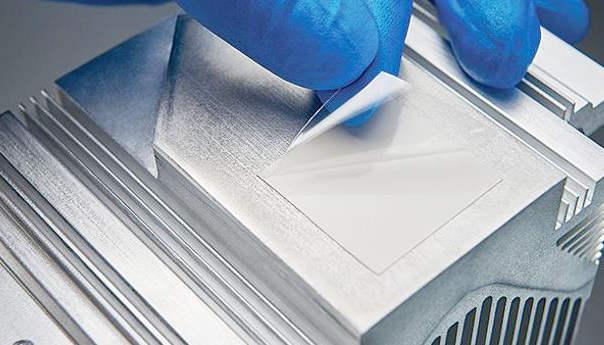

Thermal insulation and protection of chips and power modules are achieved using die-cuttable thermally conductive tapes, thermal insulation pads, and thermal interface materials (TIM).

Home Appliances

Thermal insulation tapes are applied to heating parts in devices such as microwave ovens, rice cookers, and water heaters. They provide high-temperature protection and fire isolation.

Thermal & Electrical Insulation

High-temperature and insulating tapes protect sensitive components from heat and electrical interference.

Industrial Equipment

Heat source isolation for hot air blowers, welding equipment, and laser processing equipment is achieved using thermal insulation and fireproof composite tape die-cuttings, which protect adjacent electronic components.

Let us help you find tape solutions

Discover how our die-cut heat shielding tape solutions enhance thermal protection, boost performance, and ensure safety in demanding applications. Our experts are here to help with material selection, custom designs, and seamless product integration.

Used for heat reflection and insulation, commonly used in engine compartments, air ducts, heating components.

It has both thermal and electrical conductivity, suitable for the dual needs of electromagnetic shielding and thermal control.

High strength, high temperature resistance, often used for heat source coating and mechanical protection.

Meets UL 94 V-0 standard and is used in scenarios with risk of flame propagation. Widely used in batteries, power modules, and electronic control systems.

Can replace thermal conductive glue/silicone grease for fixing electronic components and heat dissipation.

Let’s Connect with Yousan

Contact our team for one-on-one technical support and tailored adhesive tape solutions.