Technical data

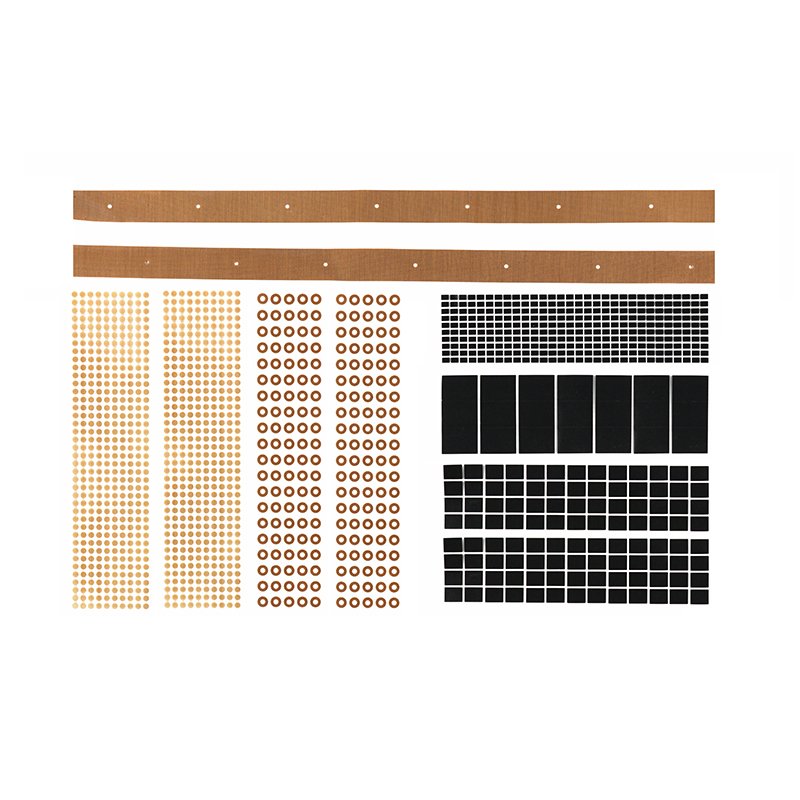

| Product Code / Technical Parameters | P0213 | P0216 | P0218 | P0225 | P0230 | P0213Y | P0213BY | P0216Y | P0218Y | P0225Y |

| Color | Brown/Black/ creamy-white |

Brown/Black/ creamy-white |

Brown | Brown | Brown | Brown | Black | Brown | Brown | Brown |

| Total Thickness[mm] | 0.13 | 0.16 | 0.18 | 0.25 | 0.3 | 0.13 | 0.13 | 0.16 | 0.18 | 0.25 |

| Backing Thickness[mm] | 0.08 | 0.08 | 0.13 | 0.18 | 0.25 | 0.08 | 0.08 | 0.11 | 0.125 | 0.18 |

| Backing | Teflon Fiberglass Cloth | |||||||||

| Adhesive | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone |

| Release material | – | – | – | – | – | Yellow release liner | Yellow release liner | Yellow release liner | Yellow release liner | Yellow release liner |

| 180°Peel Strength[N/100mm] | 21 | 22 | 22 | 24 | 24 | 21 | 21 | 22 | 22 | 24 |

| Tensile Strength[N/100mm] | 900 | 1300 | 1300 | 1950 | 2250 | 900 | 900 | 1300 | 1300 | 1950 |

| Long-Term Temperature Resistance[℃] | –70~260 | –70~260 | –70~260 | –70~260 | –70~260 | –70~260 | –70~260 | –70~260 | –70~260 | –70~260 |

| Short-Term Temperature Resistance[℃] | –70~300 | –70~300 | –70~300 | –70~300 | –70~300 | –70~300 | –70~300 | –70~300 | –70~300 | –70~300 |

Legal Disclaimer

The values given are typical values, and do not constitute a specification. We recommend testing the suitability of the self-adhesive tape for the designated application or use. Please contact us or e-mail info@ysdiecut.com to determine product availability.

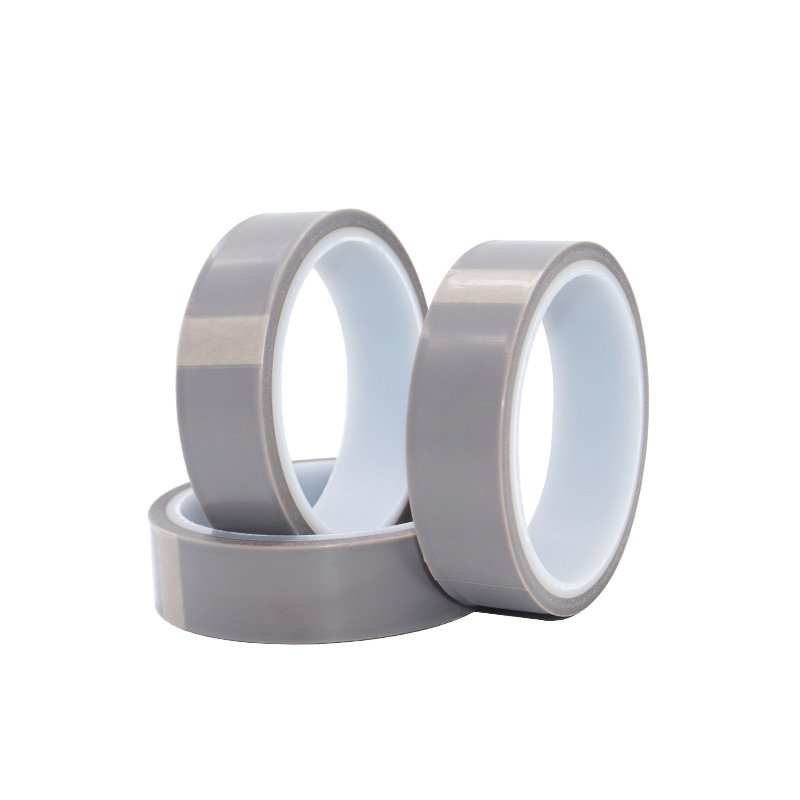

Glass Fiber Teflon Tape Manufacturer

Yousan New Materials

Storage

It is recommended to store in a clean and dry place, away from direct sunlight, to prevent damage to the packaging, and to avoid keeping it with volatile solvents. The storage temperature is 0-40°C and the humidity is <80%. To maintain optimal performance, this product should be used within 12 months from the date of manufacture.