Clean Room Die-Cutting Solutions

From sensitive optical films to medical-grade adhesives tapes, we deliver clean, consistent, and compliant die-cut solutions.

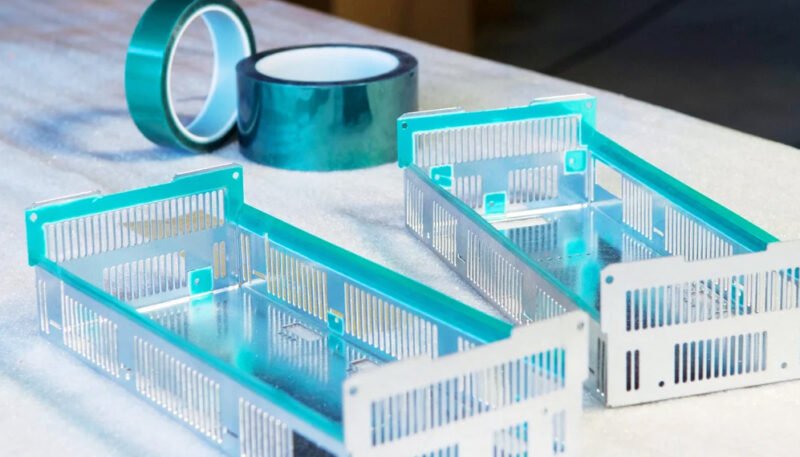

Clean Room Die-Cutting

Offers clean room die-cutting services for industries that require contamination-free, high-precision adhesive and non-adhesive components. Our ISO-certified cleanroom facilities ensure that every part meets strict standards for cleanliness, consistency, and quality—ideal for medical, electronics, display, and aerospace applications.

Contamination-Free Processing

ISO-class cleanrooms prevent dust, particles, and foreign materials—ideal for sensitive applications like medical, optical, and electronic components.

High Precision and Consistency

Our advanced die-cutting equipment ensures tight tolerances and repeatable results, even for micro-sized parts.

Material Integrity Protection

Environmental controls preserve the chemical and adhesive properties of sensitive materials during processing.

Regulatory Compliance

Meets standards required in medical, aerospace, and clean-tech industries (e.g., ISO 9001, RoHS, REACH, UL).

Custom Die-Cutting Capabilities

Supports kiss-cut, through-cut, multi-layer laminating, and liner removal in a clean, controlled workflow.

Reliable Supply for High-End Industries

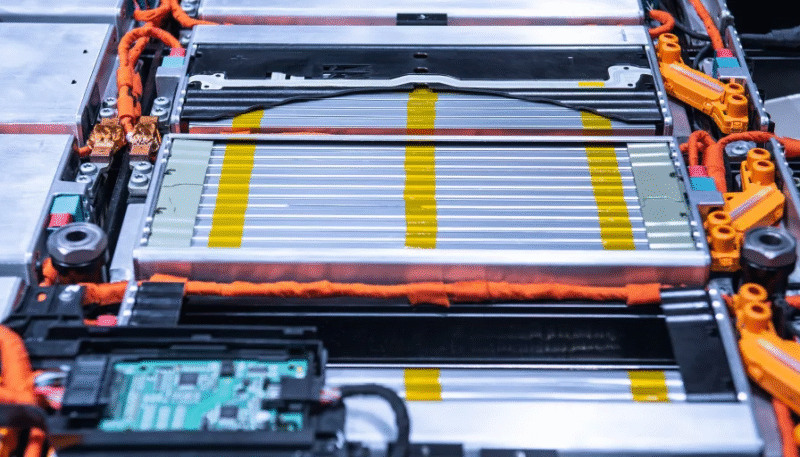

Trusted by clients in displays, semiconductors, EV batteries, and healthcare, who demand the highest cleanliness levels.

What Is Clean Room Die-Cutting?

Clean Room Die-Cutting refers to the process of cutting adhesive or non-adhesive materials into precise shapes and sizes within a controlled, contamination-free environment—also known as a cleanroom. This specialized process is essential for manufacturing components used in industries where even the smallest particle can impact product performance or safety, such as:

Cleanliness requirements for products in industries such as mobile phones, display screens, semiconductors, circuit boards, and medical treatments.

Why Clean Room Die-Cutting Matters

Clean room die-cutting is essential when manufacturing precision components for industries that demand ultra-low contamination levels, such as electronics, medical devices, semiconductors, and automotive batteries.

In these environments, even microscopic particles, fibers, or outgassing from materials can lead to device failure, reduced product lifespan, or compromised safety. Die-cutting in a certified clean room ensures that:

• Particulates and foreign matter are minimized during material processing.

• Adhesive tapes and functional films are cut in controlled conditions, preserving material integrity.

• Products meet regulatory and customer cleanliness standards such as ISO 14644 or GMP.

• There’s no secondary cleaning or costly rework needed after processing.

For high-precision, contamination-sensitive applications, clean room die-cutting is not just a benefit — it’s a necessity.

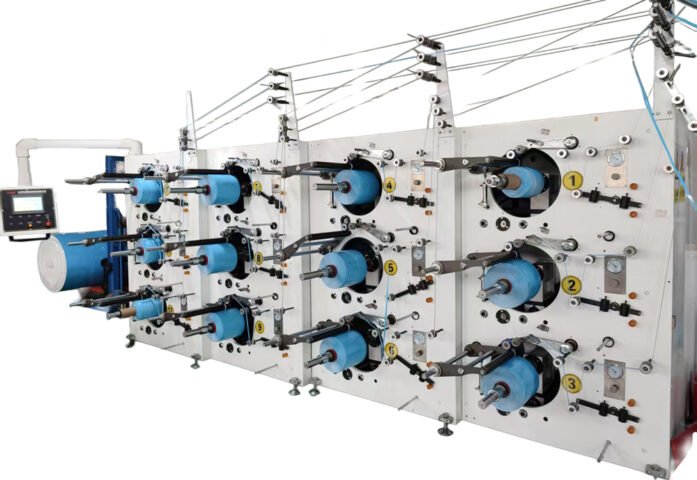

Production Process Show

Discover how high-performance tapes are made—from coating and curing to slitting and inspection. Precision at every step ensures reliable quality and performance.

Industries & Applications

Yousan tape products and die-cutting solutions are widely used in multiple high-standard industries, meeting the multi-functional needs of bonding, fixing, sealing, insulation, buffering, thermal conductivity, etc. in different fields.

Frequently Asked Questions

Find quick answers to common questions about our adhesive tapes, die-cutting services, and customized solutions. We’ve compiled the most frequently asked inquiries from our clients to help you get the information you need—fast and efficiently.

We offer a wide range of tapes including double-sided, high-temperature, conductive, foam, PET, PE, and specialty tapes for electronics, automotive, medical, and industrial use.

Yes. We provide precision die-cutting services based on customer drawings, samples, or design requirements—delivered in rolls, sheets, or individual pieces.

MOQ varies depending on the product type, size, and level of customization. Please contact our sales team for exact details.

Let’s Connect with Yousan

Contact our team for one-on-one technical support and tailored adhesive tape solutions.